Making Sustainable, Rare Actives Through Fermentation

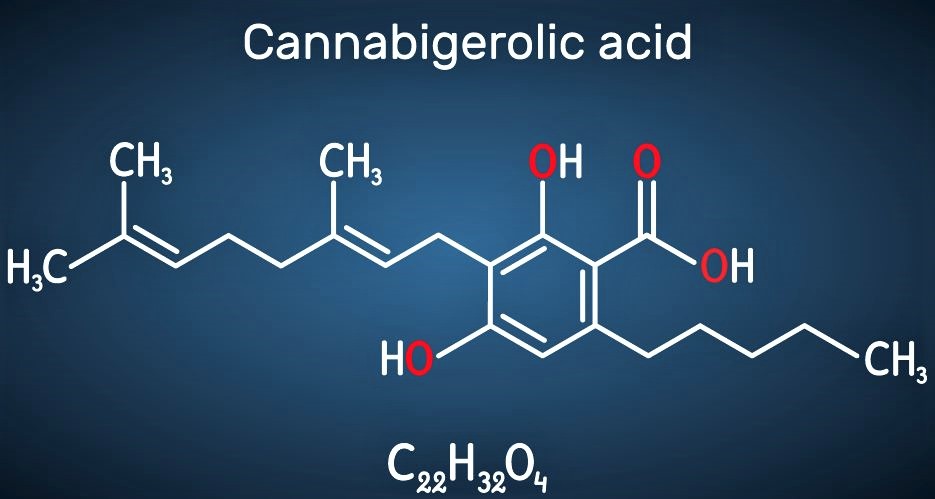

As the benefits of the Cannabis sativa plant continue to be explored and the demand for rare actives continues to increase, there will be a need for a consistent supply of pure, sustainable product.

CBD typically comprises about 10% of the plant and the rarer cannabinoids are found in even lower quantities. Many plants are unable to meet the ever-increasing productivity demands for manufacturing a variety of products, such as tinctures, capsules, shampoos, toothpaste, supplements, and vapes.

Even with the ability to engineer the plant to produce more of one cannabinoid, continued increase in consumer demand will likely require metric tonnes of each cannabinoid.

While it’s easy to believe that increasing the number of C. sativa plants grown is the solution, this comes with several drawbacks.

The Environmental Concerns

On top of productivity problems, there are several far-reaching environmental impacts of increasing C. sativa cultivation. Most cannabinoids are currently extracted from the hemp plant and the land, water, and electricity requirements for the extraction process are largely unsustainable.

With regards to water, C. sativa is known as a “thirsty” plant. During the growing season from July through October, it’s estimated that a similar area of C. sativa plants would require almost 63% more water than grapes grown for wine. Where will this water come from?

There’s also the unused biomass to consider. This is the part of the plant that’s left over after cannabinoid extraction. While it may seem like it could simply be composted, reused, or returned to the soil, these are massive amounts of plant waste. It’s simply not feasible to repurpose all of it.

Finally, cannabis farms can displace wildlife, including endangered and native plant and animal species, and require additional infrastructure (i.e., roads and buildings) to support supply and distribution. Taken together, there is a massive (and unappreciated) amount of environmental impact to cannabis farming and plant-based cannabinoid extraction.

We all want the benefits of these plant-derived compounds, but at what environmental cost?

The Fermentation Solution

This is where fermentation comes in. With fermentation, yeast are programmed to make the exact same cannabinoid as the plant. Regardless of how rare the cannabinoid, the yeast can make almost the same amounts in the same reactors, with similar amounts of reagents and much reduced environmental impact compared to plant-based extraction.

Bioreactors take up less land mass than plants and use less water. They also have fewer carbon emissions and minimal biomass.

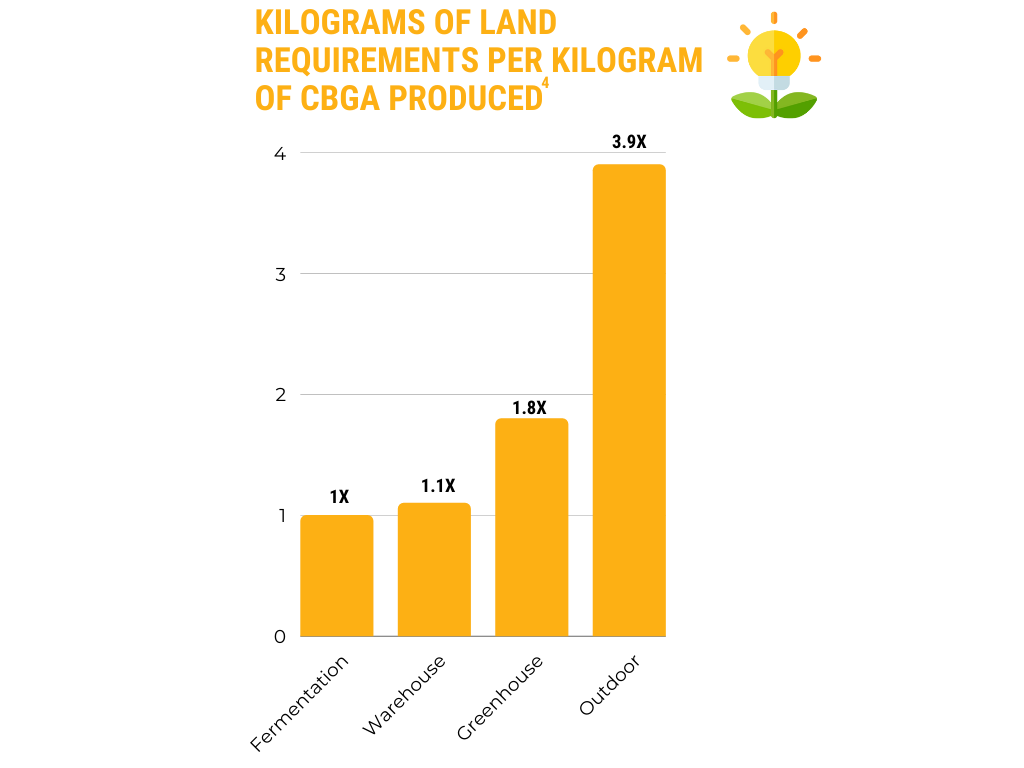

If we compare CBGA, the mother cannabinoid, produced in different ways, it’s easy to understand the benefits of fermentation.

First we can look at the difference in land use. CBGA grown outdoors requires 3.9 times more land than the same amount produced through fermentation.

Water usage shows an even greater difference. One kilogram of CBGA grown outdoors requires 340 times more water than the same amount produced through fermentation. While greenhouses do better than outdoors in this category, they’re require 59 times more water than fermentation.

Lastly there are the carbon emissions. Greenhouses emit 158 times more carbon dioxide than fermentation, while outdoor production produce 45 times more.

The rarer the cannabinoid, the greater the benefit of using fermentation. Consider the magnification of benefits with CBN or CBC which comprise less than 1% of the plant.

Can The Plants Be Modified to Make More Cannabinoid?

As you can see from the numbers, the C. sativa plant would require traditional crop breeding or genetic modification programs to produce 340% more CBGA to match the water requirements for fermentation.

If we consider reducing the number of plants required to produce a certain amount of cannabinoid, the amount of cannabinoid the plant must make becomes difficult to obtain.

The rarer the cannabinoid, the more unlikely it becomes that modifying the plant can meet the current or future demand.

But Aren’t the Plant-Derived Cannabinoids More Natural?

We understand the desire for plant-based products. And so do today’s consumers. We love our herbal remedies and home gardens.

One thing that’s important to understand is that extracting compounds made by a plant or fermented by yeast, especially on the scale required for nutritional supplements or cosmetic products, requires chemicals.

After cannabinoids are extracted from other plant or yeast compounds, they must then go through additional purification steps to ensure any harmful materials, whether they be plant-derived, yeast-derived, or used in extraction, are removed.

At the end of the purification process, both final products are still based in nature and can be considered “natural.”

This is true of many plant-based products on the market. Every government has regulations that you must follow and specifications you must meet before providing your final product to consumers. This generally requires additional processing.

Does This Mean Agriculture is Bad For the Environment?

Agriculture is a tried-and-true method of providing food and essential ingredients for so many different industries. Farmers know how to use the land to provide us with excellent resources. In many ways, sustainable agriculture is important to the environment, our health, and our culture.

Demand for cannabinoids is at an all-time high, yet there are currently few regulations governing cannabinoid agriculture. There is no precedent for the current situation that the cannabinoid industry finds itself in, which means farmers, suppliers, and governments are having to develop and implement mandates as they move forward.

To paraphrase an old colleague, we’re putting the wheels on the train while it’s pulling out of the station.

Even with additional regulations overseeing the hemp supply, there remains the simple matter of supply and demand. Currently, agriculture alone cannot meet the current demand.

Fermentation is a more scalable and controllable process that allows cannabinoids to be produced more sustainably, at higher purity, and at a lower cost than traditional methods.

To learn more about our technology and products, please Contact Us.